Mechanical Lippage Tuning Tile Leveling System 250 Piece Reusable Caps

The MLT system consists of three major components: Reusable Caps, Reusable Straps, and Base Plates. This system achieves the least amount of waste possible. With four different Base Plates to choose depending on the type of material, in addition to Cap accessories, such as the rubber foot for soft stone it allows the MLT Professional Lippage Tuning System to be tailored to each specific job.

Features

- Designed and engineered to be disengaged under tension to allow cleaning of grout joints and seams, or to re-position the tiles/slabs just with a slight side pressure

- To guarantee the perfect alignment and plane during the curing of the setting material

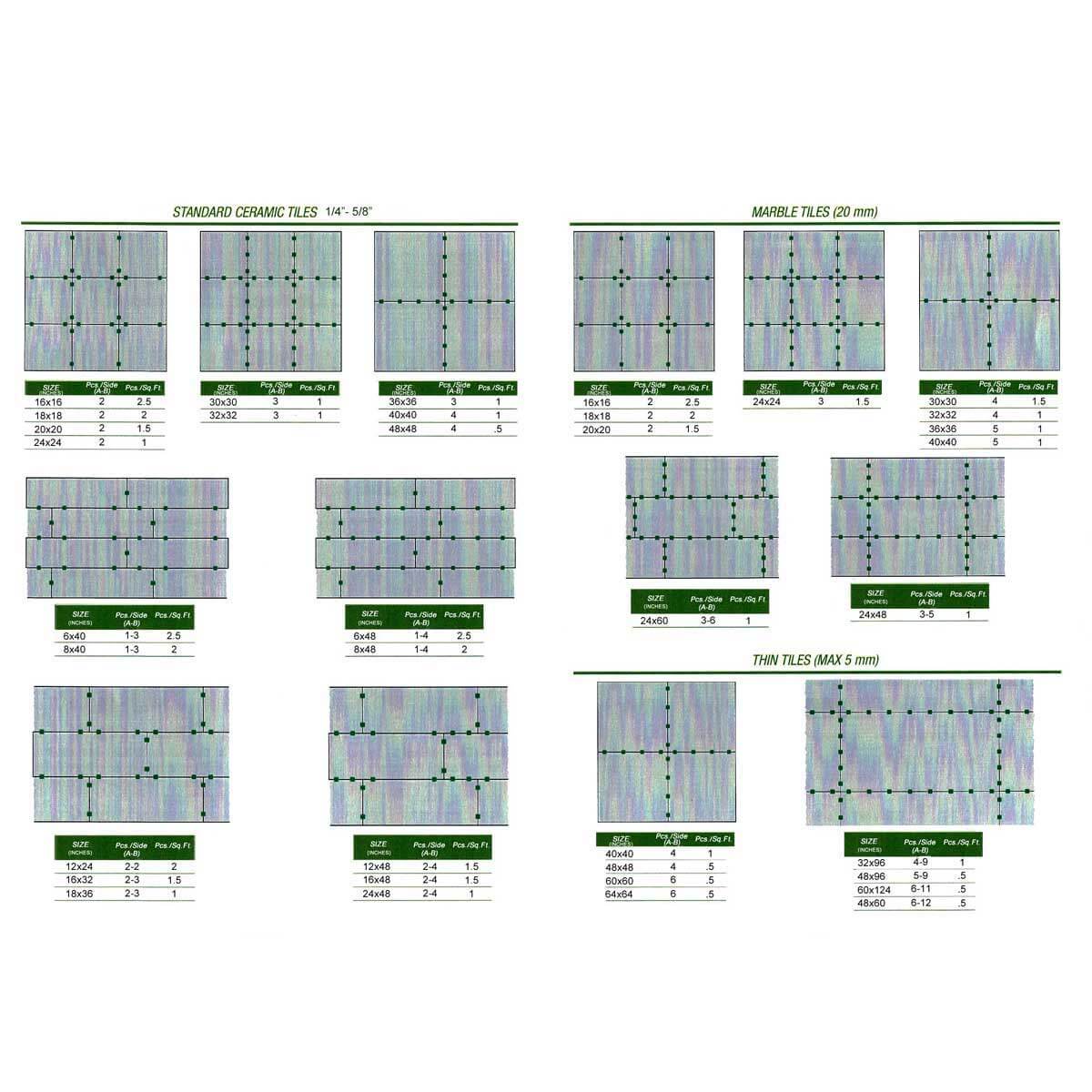

- Base Plates for Porcelain, Thin Tile, Porcelain, and Stone with even offset joints

- Reusable straps can be used multiple times, lowering overall expense

- No need to pre-soak Base Plates

- Rubber Feet and Steel Tongue Inserts for Caps avoid scratching and extend Cap life

- Counter sink holes in Base Plates aid in fastening for ceiling applications

- Base Plate design allows for maximum thinset coverage without hollow spots

- The slot on the top of the cap will accept a Stainless Steel tongue insert in cases where the ratcheting teeth may become worn. This will greatly prolong the working life of each cap

MLT System Installation

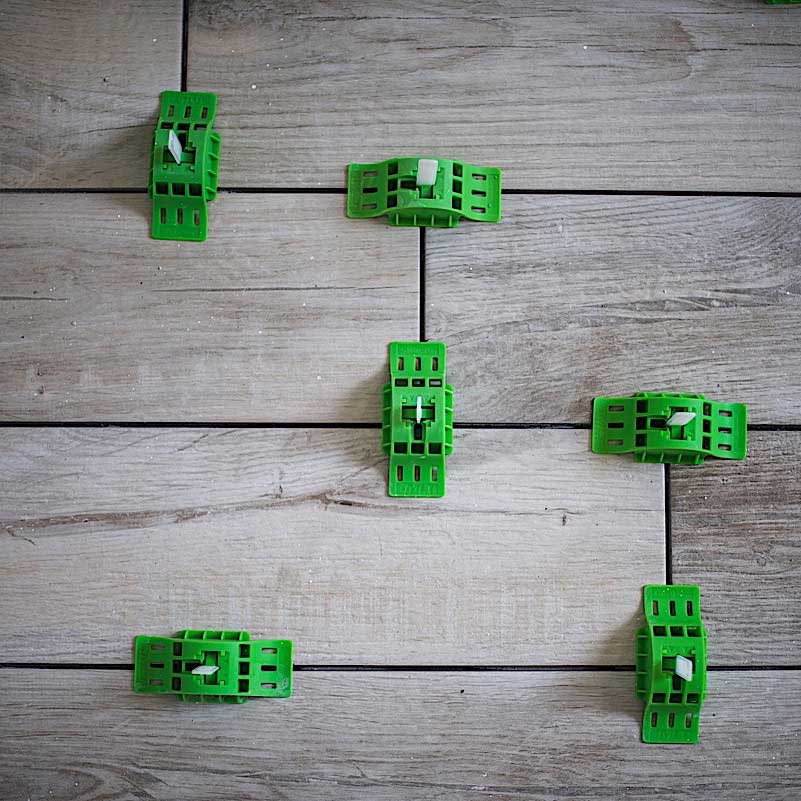

- Pre-assemble reusable connecting tab and base plate

- Push stainless steel portion of the re-usable connecting tab through the center opening of the selected base plate

- Align protuberances by passing them completely through the slotted openings of the stainless steel connecting tab

- Pull connecting tab until the "snap lock" engages

- Base plate should remain affixed to re-usable connecting tab unless separation is desired

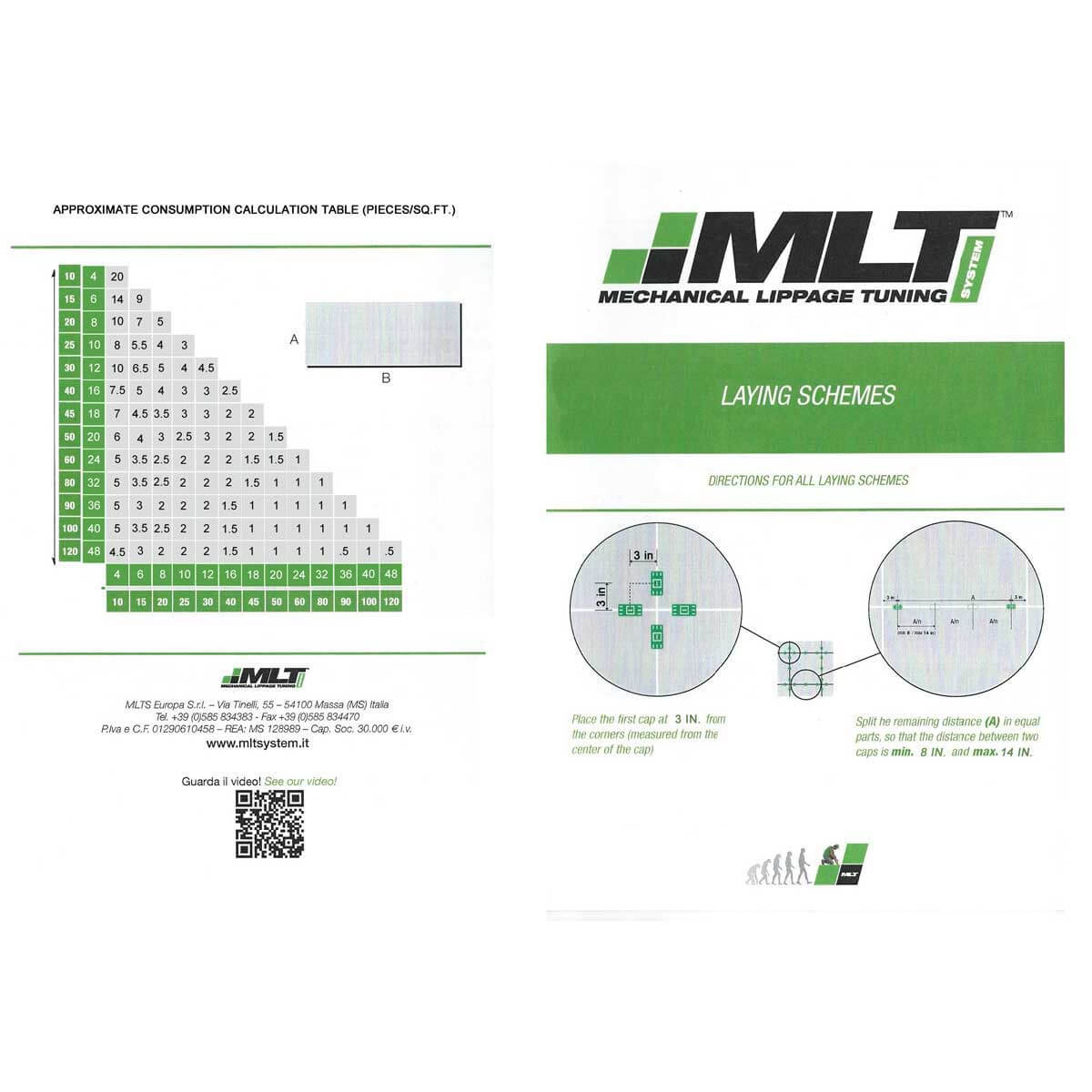

- Insert pre-assembled re-usable connecting tab and base plate under the tile or stone edge, sliding the connecting tab's base plate under the tile or stone being installed, at approximately 3” from the corners (MLTSystem components may be used for the corners of an offset pattern, in the “T” intersection of porcelains having a minimum thickness of 3/8”)

- Spacing of each re-usable connecting tab should not exceed 20” to 24” apart, during installation

- Do not place them under a four-corner junction as lippage may result and also greatly increase the difficulty to produce a straight grout joint line

- Once the pre-assembled re-usable connecting tab and base plate is in place, proceed using standard installation procedures

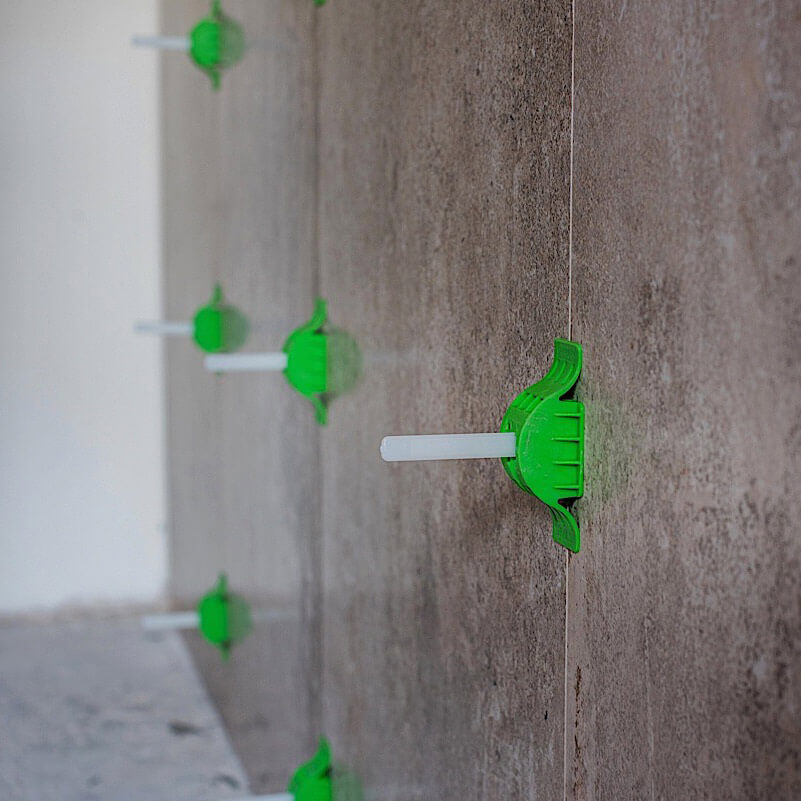

- Upon completing the "set" of the tile or stone, lower the tension locking cap over the re-usable connecting tab to tile or stone surface then, slide cap in direction of the grout joint to engage the lock

- Place installation/removal tool atop the tension locking cap to engage the re-usable connecting tab and tension MLT System, to create a lippage free surface

- If additional cleaning of grout joint line is required after MLT System has been tensioned: remove cap, clean joint line, re-engage cap and re-tension

- To remove set tension setting dial on “S” for “Snap”. Place installation/removal tool atop re-usable cap and engage the re-usable connecting tab

- Collect and store all re-usable connecting tabs and re-usable tension locking caps, for future use

- When using MLT System for installations of thin tile, un-glazed, or highly polished materials, it is strongly recommended to use the fitted Rubber Pad accessory under the re-usable tension locking cap